In recent years the demand for using PET bottle waste to produce also thermoformed sheet has been growing steadily. Several technologies were applied, all of them trying to avoid drying of flakes (with relative high costs) before being fed to the extruder. In order to keep manufacturing costs down, BG Plast has prepared a single screw extruder equipped with a gravimetric dosing unit, falkes, virgin material and masterbatch.

The sheet thus obtained guarantees high quality, with a minimum loss of I.V. (Intrinsic Viscosity) measured in the extruded sheet in relation to initial waste values.

It is well known how strongly moisture influences the I.V. of the PET product to be later thermoformed. Such moisture can be thoroughly eliminated by means of a very efficient vacuum system equipped with a high performance special pump.

The use of the sheet for food packaging requires that only virgin material may have contact with foodstuffs.

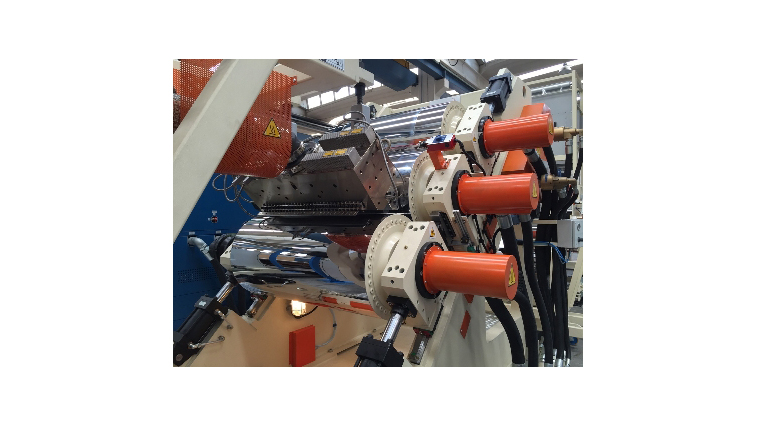

Therefore the central extruder, fed with flakes, is complemented by a co-extruder to be fed with virgin material.

This allows the production of a multi-layer sheet A-B-A in a 5-90-5% ratio, respectively.

Downstream equipment is similar to that of a PP or PS sheet standard line, with the addition of a silicon bath along the extrusion line.

In order to be competitive from all points of view, BG Plast has recently close an important agreement with a well known European manufacture of twin screw co-rotating extruders.