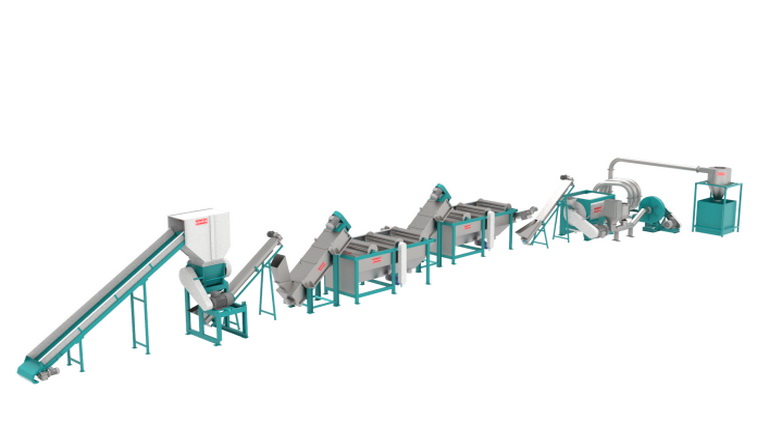

PP Raffia Bag Washing Line

Panchal Plastic develops and manufactures customized PP big-bag recycling plant. They’re utilized to store and transport granules or powder products from a variety of industries, including mining, chemicals, and agriculture, as well as rubber, resin, fertilizer, construction, and food. Panchal Plastic big bag recycling facilities have input capacities ranging from 500 kg/h to 1000 kg/h.

Special Design Features:-

– The PP raffia bag washing system was created to wash PP raffia bag with contamination.

-Grinding machine is specifically designed for rigid materials to produce standardized particle sizes that are easy to wash and dry.

-Friction Washer is used for remove dirty and sands by the centrifugal force producing by the high-speed rotating of the rotor.

-Sink-float tank is used for floating material like film/lables like LDPE/HDPE/PP etc on the top and at the bottom all the sink material ilke PVC/PET/PC etc. both have different Discharge point to collect different material, based on density.

-The moisture content of the finished product is regulated by horizontal dryers and thermal drying systems. The material is ideal for high-quality pelletizing at a moisture content of less than 5%.